The Wind Lift 1, the service and installation vessel of Bard Engineering Group, has a lot to do.

Alone the foundation of a commercial installation in an offshore park weighs more than 1000 tons. In addition, the piles with a length of approx. 70 metres weigh about 210 tons each. Therefore suitable transport and assembly must be ensured. For this, Bard Engineering Group has an appropriate answer. With the Wind Lift 1 the company in Bremen developed a vessel which meets the requirements for offshore installations.

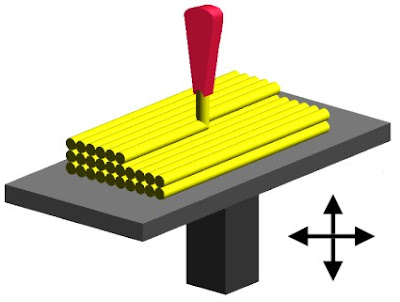

Plenty of tests and simulations were done. Using models on a scale of 1:40 the new foundation structure and the vessel were exposed to much stress in the wave tunnel of the Technische Universität Berlin - and found to be good.

Even wave heights are no problem any more. The Wind Lift 1 can lift itself with its legs of 72 metres. Despite its high balance point and a draught of only 3.5 metres the 103.8 metre long ship, which is relatively wide with its 36 metres, can travel at up to 10.1 knots even with a wind force of 11.

Image source: Bard Engineering Group

More information:

http://www.bard-offshore.de/en/~

The magazine Wirtschaftswoche writes on the company Bard Engineering GmbH: "Hardly anybody believed that the company Bard in Bremen, newly founded in the wind business area in 2003, could pioneer in wind farms. All the more so that nobody could assess the entrepreneurial abilities of the then 68 year old founder Arngolt Bekker."